Competitions & Awards

2010 Prize Winners

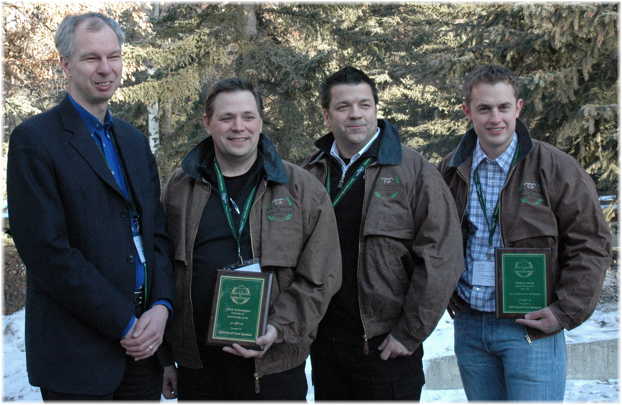

F.X. Aherne award winners, left to right: Ruurd Zilstra (committee chair), Alain Lefebre & Stephane Clement, JYGA Technologies, QC and Thomas Jacob, Genetic Alliance Ltd, AB (missing - Paul Wurz)

The winners of this year’s F.X. Aherne Prize for Innovative Pork Production include Paul Wurz of Butte Colony in Bracken, Sask., Stephane Clement and Alain Lefebre of JYGA Technologies in St. Nicolas, QC, and Thomas Jacob of Genetic Alliance Ltd., in Acme, AB.

"All three of this year’s award winners are very deserving," says Ruurd Zijlstra of the University of Alberta, chair of the F.X. Aherne prize committee. "These awards honor the memory of Dr. Aherne, who was responsible for a number of innovations that the pork industry still benefits from today," says Zijlstra. "They are an important recognition of those who continue to make innovative contributions to the pork production industry."

Paul Wurz received the award for his invention of a "pregnancy check extension." This extension, which fits onto a typical pregnancy checking tool, allows for pregnancy checking sows from the front of stalls, or from the back, without bending over or getting into the stall. This innovation can also be used to pregnancy check sows or gilts in group pens, when a bit of feed is placed on the floor to keep the livestock occupied and still.

Stephane Clement and Alain Lefebre earned the prize for their invention of the gestalt feeding station, a computerized feeding system for farrowing sows. The feeder communicates with a computer using wireless technology and provides sophisticated management feedback to the farm that offers many possibilities to optimize the productivity of each sow and the follow-up of the herd. The invention is touted as a simple solution that will feed small amounts of fresh feed on demand by the sow, resulting in less feed wastage. The data it gathers provides a wealth of information to support farm management.

The recognition for Thomas Jacob was for his innovative new design for a safe and efficient boar training pen. Highlights of the system, which is based on a two-dummy method, are up to 90 percent success rate in the first training session and the ability to train up to 10 boars per hour, resulting in major time and cost savings.